If you’re producing pre-rolls in California, you already know how demanding the process can be. Between compliance requirements, labor costs, and keeping quality consistent, hand rolling only works for so long. Once demand starts climbing, you need equipment that helps you scale without sacrificing the product your customers expect.

Pre-roll machines are very different than they were even a few years ago. Today’s systems are faster, more precise, and designed to meet the needs of licensed producers operating under California regulations. Whether you’re running a boutique operation or a high-volume facility, choosing the right machine can make a real difference in your daily workflow.

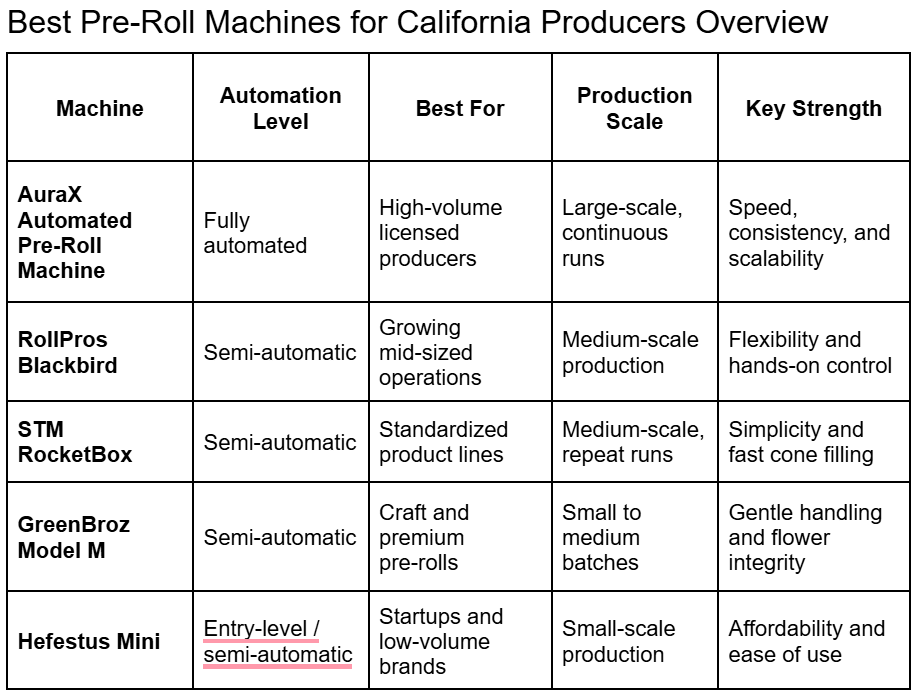

Below are five of the best pre-roll machines available to California cannabis producers right now. We’ll start with the top option and then walk through a few solid alternatives, followed by some guidance to help you decide what’s right for your operation.

1. AuraX Automated Pre-Roll Machine

If you’re looking for a commercial joint rolling machine that is is built for speed, consistency, and reliability, the AuraX stands out as the top choice.

The AuraX is built specifically for producers who need automation without losing control over quality. It handles grinding, filling, tamping, and rolling with impressive accuracy. That means each pre-roll comes out uniform in weight, density, and appearance, which is critical when you’re selling into a regulated California market.

Scalability is where the AuraX really pulls ahead. You can run it continuously throughout the day, making it ideal for producers filling wholesale orders or supplying multiple dispensaries. It also reduces labor strain. Instead of relying on teams of rollers, you can reassign staff to packaging, QA, or other high-value tasks.

Ease of use is another reason it ends up at the top of the list. The interface is straightforward, training time is minimal, and cleaning is manageable even during busy production weeks. For producers focused on long-term growth, it’s a machine that supports expansion instead of slowing it down.

2. RollPros Blackbird

The RollPros Blackbird sits in the middle ground between hand rolling and full automation.

This machine still requires some manual input, but it significantly speeds up production compared to hand rolling. It’s especially useful for producers who want control over flower placement and cone density while increasing daily output.

What producers tend to like about the Blackbird is how adaptable it is. You can switch cone sizes and strains quickly, which is helpful if you’re running multiple SKUs. While it doesn’t match the output of a fully automated system, it’s a reliable step up for brands transitioning out of manual production.

3. STM RocketBox

The STM RocketBox is built for producers who prioritize speed and simplicity. It’s compact, efficient, and designed to handle consistent runs without too much adjustment.

This machine is well-suited for facilities with limited space. It focuses on filling cones quickly and evenly, making it a solid option if your pre-rolls follow a standardized format.

The RocketBox works best in environments where repeatability matters more than customization. If your menu doesn’t change often and you want predictable results day after day, it can be a dependable part of your production line.

4. GreenBroz Model M

The GreenBroz Model M approaches pre-roll production with a gentler process. It’s designed to preserve flower structure while still improving efficiency.

Many California producers appreciate this machine for premium or craft pre-rolls. It allows you to maintain a hand-finished feel while reducing the time it takes to fill cones. It’s not built for massive volume, but it fits well in operations where brand image and flower integrity matter most.

This machine is often used alongside other equipment rather than as a standalone solution. If you’re producing smaller batches or specialty runs, it can be a useful addition.

5. Hefestus Mini

For startups or low-volume producers, the Hefestus Mini offers a more accessible entry point into mechanized pre-roll production.

It’s compact, easy to operate, and designed for teams that don’t need full automation yet. While output is limited compared to larger systems, it still improves consistency and reduces hand strain.

This machine is best suited for new brands testing the market or producers who want to bring pre-roll production in-house without a major upfront investment.

What California Producers Should Look for in a Pre-Roll Machine

Not every machine is right for every operation. Before you invest, it’s worth thinking about how the equipment fits into your broader production goals.

Volume requirements matter more than anything else. If you’re filling thousands of pre-rolls per day, automation isn’t a luxury. It’s a necessity. Machines like the AuraX are designed for that level of demand, while semi-automatic systems can struggle under sustained high output.

Consistency is another key factor. California compliance testing doesn’t leave much room for variation. Weight discrepancies and loose fills can lead to failed batches and lost revenue. A machine that delivers uniform results helps protect your margins.

You should also consider labor efficiency. With rising labor costs across the state, reducing repetitive manual tasks can have a big impact on profitability. Automated systems free up your team to focus on quality control and fulfillment instead of rolling cones all day.

Compliance Considerations for Pre-Roll Production in California

California’s regulatory environment adds another layer of complexity to pre-roll production. Beyond basic efficiency, your equipment needs to support compliance at every stage of the process.

Weight accuracy is one of the biggest factors. Even small inconsistencies can trigger failed quality checks or require costly rework. Machines that offer precise filling and repeatable results help reduce the risk of underfilled or overfilled pre-rolls, which is especially important when products are tested and labeled for sale.

Sanitation and cleanliness also matter. Pre-roll machines that are easy to disassemble and clean make it easier to follow good manufacturing practices. This not only protects your product but also helps during inspections and audits. Equipment that’s difficult to clean can slow production and increase downtime.

Documentation is another overlooked benefit of automation. Consistent output makes batch tracking simpler. When your production process is predictable, it’s easier to document quantities, inputs, and yields, which supports compliance reporting and inventory management.

Labor Challenges and Why Machines Matter More Than Ever

Labor has become one of the biggest operational challenges for California cannabis producers. Finding reliable staff, training them, and keeping them long-term is expensive. Hand rolling, in particular, is repetitive and physically demanding, which leads to higher turnover.

Pre-roll machines help reduce reliance on large rolling teams. Instead of needing several employees focused on a single task, one or two trained operators can manage a machine while the rest of the team focuses on packaging, labeling, or quality control.

This shift doesn’t just reduce costs. It improves morale. When employees are doing varied work instead of repetitive rolling, they tend to stay longer and perform better. Over time, this stability makes production planning easier and reduces disruptions caused by staffing shortages.

For producers looking to scale, labor efficiency often becomes the deciding factor in whether automation makes sense. Machines allow you to grow output without growing headcount at the same pace.

Matching Machine Output to Market Demand

Not every California producer needs maximum output right away. Choosing the right pre-roll machine often comes down to aligning capacity with real demand.

If you’re running limited drops, seasonal products, or specialty strains, flexibility may matter more than speed. Semi-automatic systems can handle variety without locking you into one format. These machines are easier to adjust and work well for brands that rotate SKUs frequently.

On the other hand, if your pre-rolls are a core revenue driver, high-capacity machines become essential. Wholesale accounts expect consistent supply, and missed delivery windows can damage relationships. Automated systems help ensure you can meet orders without scrambling to add labor or overtime.

Planning for growth is key. Many producers choose machines that slightly exceed current demand so they’re prepared for new accounts or expanded distribution.

Reducing Waste and Protecting Margins

Flower waste is a hidden cost in pre-roll production. Inconsistent fills, dropped material, and rework all cut into margins. Over time, these losses add up.

Well-designed pre-roll machines help minimize waste by controlling how flower is handled and distributed. Automated grinding and filling systems reduce spillage and ensure material goes where it’s supposed to.

Consistency also reduces rejected units. When pre-rolls come out uniform, fewer need to be opened, adjusted, or discarded. That efficiency directly impacts profitability, especially as flower prices fluctuate.

For California producers operating on tight margins, reducing waste can be just as valuable as increasing speed.

Integrating Pre-Roll Machines Into Your Production Line

Buying a machine is only part of the equation. How it fits into your existing workflow matters just as much.

Producers often see the best results when pre-roll machines are integrated alongside grinding, packaging, and labeling stations. When everything flows smoothly, production becomes more predictable and less stressful.

Space planning is important here. Compact machines work well in smaller facilities, while larger automated systems may require layout changes. Thinking through these logistics upfront helps avoid disruptions once the machine arrives.

Training also plays a role. Machines with intuitive interfaces and clear controls reduce ramp-up time and help new operators get comfortable quickly.

Long-Term Value Versus Upfront Cost

It’s easy to focus on the price tag when evaluating pre-roll machines, but long-term value matters more. A lower-cost machine may seem appealing at first, but if it limits output or requires frequent maintenance, it can become a bottleneck.

Higher-end machines often pay for themselves through labor savings, reduced waste, and increased throughput. For producers planning to stay competitive in California’s market, these efficiencies add up over time.

Thinking beyond the first year helps clarify the real return on investment. Machines that support growth, compliance, and consistency tend to deliver more value as your operation scales.

How Automation Changes Your Production Workflow

Switching from hand rolling to machine-assisted production often changes more than just speed. It affects how your entire operation runs.

You’ll likely see fewer bottlenecks in packaging since pre-rolls come out more consistent and ready to move down the line. Inventory planning also becomes easier when output is predictable. Instead of guessing how many units your team can roll in a day, you can plan with confidence.

Automation also supports brand growth. When you know you can meet demand without sacrificing quality, it’s easier to pursue new wholesale accounts or expand into new California markets.

Choosing the Right Fit for Your Brand

The best pre-roll machine is the one that aligns with where your brand is headed. If you’re aiming to scale aggressively, investing in a commercial joint rolling machine like the AuraX can save you time, labor, and headaches down the road. If you’re still building your presence, a smaller system may be enough for now.

Either way, upgrading your production process is a step toward consistency, compliance, and long-term growth. In a competitive market like California, having the right equipment behind your brand can make all the difference.